Customized solutions

Besides high quality, there are many customization options to choose from. Some of these, usually characteristic of craftsmanship, are skillfully adapted and integrated into industrial processes.

Marking and colors

The ideal solution to customize and make the product unique.

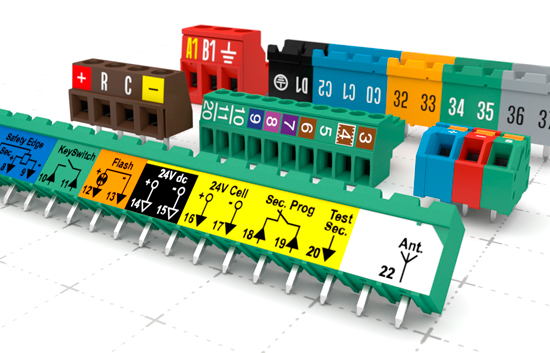

Marking

Customized marking is an ideal solution for distinguishing the product on the PCB and thus ensuring no errors during use. Sauro performs pad printing using a bi-component ink, achieving the highest possible legibility, indelibility and scratch resistance. Pad printing can be standard (numbers in progression) or customized with sequences of characters, numbers or symbols with different sizes, colors, orientation and positions.

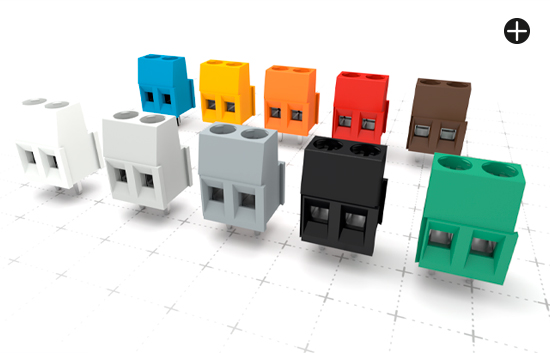

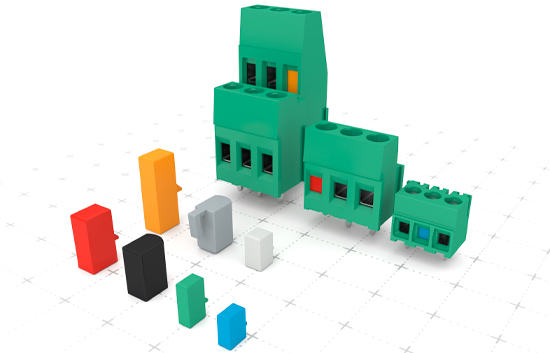

Colors

Sauro offers a wide range of colors to customize products, providing an ideal solution for distinguishing the product on the PCB and thus ensuring no errors during use. Green (similar to RAL 6032) is the standard color of traditional products, suitable for manual, selective or wave soldering, while black (similar to RAL 9005) is the standard color for STH and SMD products, suitable for reflow soldering. Both standard and high temperature products are available in additional colors upon request.

Design-in

Due to the flexibility of molding tools and philosophy of being oriented towards customer needs, plastic housings and metallic components can be designed and manufactured according to the customer required specification.

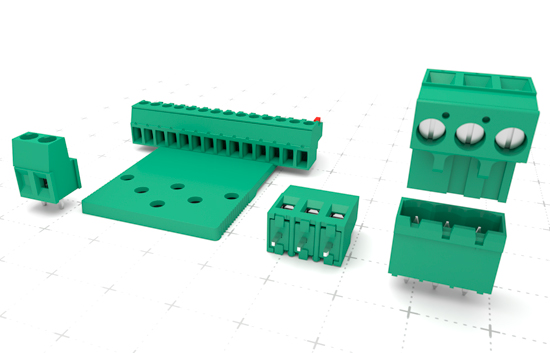

Design-in plastic housing

Due to the flexibility of molding tools and philosophy of being oriented towards customer needs, plastic housing can be designed and manufactured according to customer required specifications.

Examples of customizations: non-fundamental geometric plastic housing changes, closed product base, closed wire entry to avoid wiring of that specific pole, header and plug with integrated keyed polarization for a distinct and safe connection, peg with dual function (integrated polarization for a distinct and safe assembly on the PCB and a stronger anchoring on the PCB for higher stability during the wire tightening process or reflow soldering process), wire tension release accessory.

.

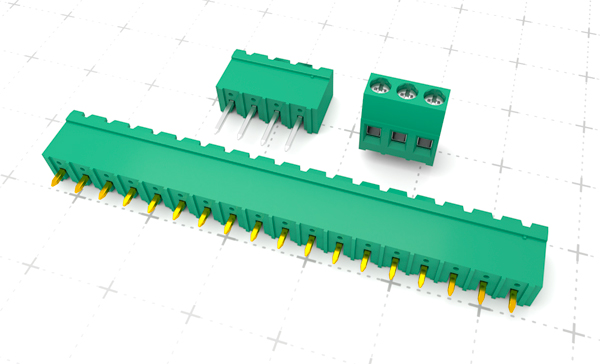

Desig-in metallic components

Due to the flexibility of molding tools and philosophy of being oriented towards customer needs, metallic components can be designed and manufactured according to customer required specification.

Examples of customizations: customized pin length, special plating such as gold plating, various screw head types different from the standard slotted one, clamp supplied closed, customized spring gap, dedicated grounding pins.

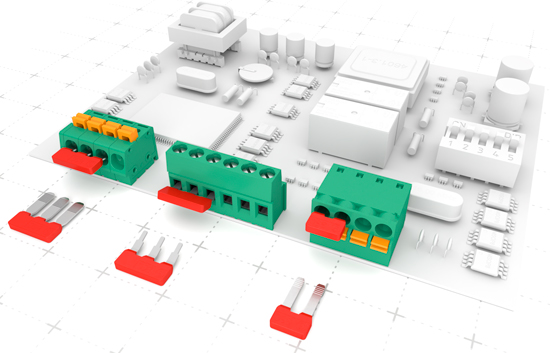

Accessories

Various accessories supplied separately or already mounted to the product.

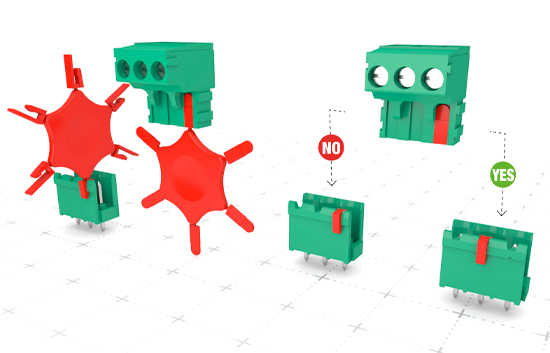

Coding element

Coding elements are made of a red plastic colored polyamide which is V0 class self-extinguishing according to UL94. For more information please download the overview sheet. To avoid the use of coding elements, thanks to the modularity of the plastic housing molds, coding integrated directly into the housing itself can be realized.

Datasheet

Using the bridge element a short circuit between adjacent poles is obtained. It can also be used to connect points on the PCB. Sauro’s bridge element element meets the safety and environmental requirements demanded by the strictest international standards. The metallic part is made with copper alloy with a lead free tin treatment surface and the insulating part is made with polyamide which is V0 class self-extinguishing according to UL94. For more information about the different bridge elements available, please download the overview sheet. The bridge element can be supplied already mounted on the product according to customer request. To avoid its use thanks to the flexibility of the available tooling the short circuit bridge can be realized directly within the product.

Datasheet

The occluder element is used to close the wire entry on screw type products or to impede the plug-header connection. It is made of polyamide material which is V0 class self-extinguishing according to UL94. The standard color is green, but it is available also in different colors. For more information please download the overview sheet. Occluder elements can be supplied already mounted to the product according to the customer request. Thanks to modular molds of the insulating housing, pole closures can be done directly when molding the housing itself.

Datasheet

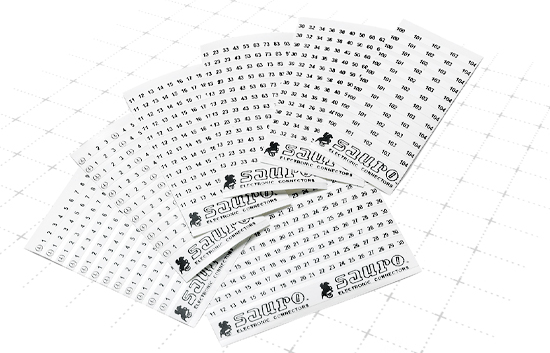

Adhesive label

The ESA series of adhesive labels are available for all pitches, with progressive numbering (standard label) or with sequences of characters with different sizes, orientation and positions (custom label). They are made of white solvent free and stain resistant polyester and are supplied with the characters printed in black with maximum readability. The labels are UL and CSA approved and their application is the responsibility of the user.

Datasheet

Packaging

Diversified packaging solutions according to PCB assembly technology or according to customer’s request

Packaging for automation

Tape on reel, cell tray and tube are ideal packaging solutions for automated PCB assembly of high temperature through hole (STH-THR-PiP) and SMD products. Tape on reel and cell tray are designed according to the specific product and manufactured internally. STH and SMD products are designed to be picked up with pliers or with suction pipette, without the need for pads or kapton dots. The solution without a pad or kapton dot is always to be preferred, since, in addition to incurring a not inconsiderable increase in the product price, they are then to be removed manually and are a special waste that must then be handled.

View more

Standard packaging

Each product is supplied in its own standard box which contains a specific product quantity.

Industrial packaging

Industrial packaging is available for large product quantities. The product code for industrial packaging is indicated by adding -00000E to the end of the standard part number.

Kit packaging

Kit packaging allows for simplified product handling, shipping, storage and assembly, as well as reduced risk of error. Sauro offers different type of kits, such as: a bag with various products inside based on PCB assembly configuration, a carton with various products packaged separately to optimize the PCB assembly process, various modular products hooked together and numbered by marking so that the subsequent sequential separation optimizes the PCB assembly process.

Certifications & declarations

Company strategy of continuous improvement and full respect and protection of people and the environment

Full compliance to RoHS since the very beginning

Full compliance with REACH regulation

All suppliers of raw materials are complaint to CMRT and EMRT

Compliance with the requirements of Prop65

The use of halogen is limited under 900 ppm

No use of persistent organic pollutants in materials used

No content of PBT substances listed in TSCA regulation

No content of per- and polyfluoroalkyl substances (PFAS)