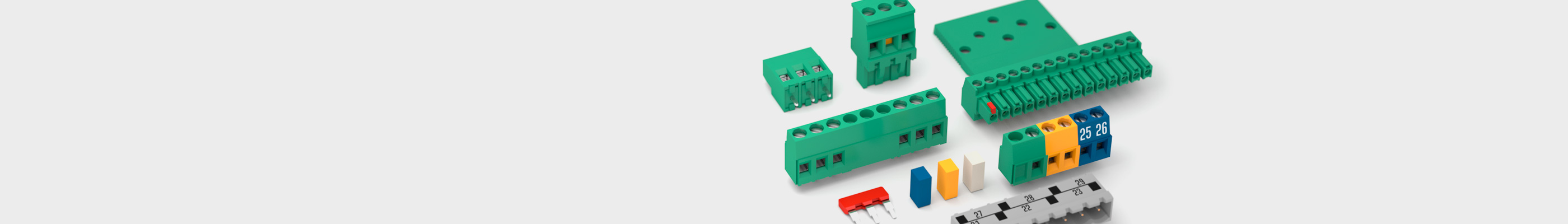

Metallic components

Due to the flexibility of tooling and the SAURO philosophy of being oriented towards the needs of the customer, the metallic components can be designed and manufactured according to the required customization.

Examples include:

– soldering pins in different lengths from the standard

– clamp with an enlarged slot

– clamp supplied closed or open

– special plating, such as gold plating

– cross or cross and slotted screw heads

– customized spring gap

– “fake” pins for anchoring and polarization

– dedicated grounding pins

Clamp

The rising cage clamp technology consists of a process starting from a solid bar in special copper alloy and then nickel-plated, obtaining components of high stability and strength suitable for aggressive and tropical environments.

Clamps with standard geometry are available from stock or can be made to customer specifications.

Slotted screws

Screws are made from metal wire containing special copper alloy and then nickel-plated. Thus obtaining a decidedly superior mechanical resistance then regulatory requirements. The material used is similar to that of the clamps to avoid electrolytic corrosion.

Screws with standard geometry are available from stock or can be made to customer specifications.

Cross & Slotted screws

For Pozidriv screws the general characteristics are the same as standard screws. The special shape of the screw head allows use of both the Phillips cross screwdriver and the traditional screwdriver.

Screws with standard geometry are available from stock or can be made to customer specifications.

Cross screws

The mechanical characteristics of the Phillips screw heads are superior to that of the standard screws.

Screws with standard geometry are available from stock or can be made to customer specifications.

Soldering Pins

The soldering pins are made of special copper alloy and then nickel-plated and tinned for an optimum soldering and to avoid the dangerous Whiskers phenomenon.

The mechanical resistance, electrical resistance and both electrical and thermal conductivity are optimized for maximum reliability of the electrical connection.

Soldering pins with standard geometry are available from stock or can be made to customer specifications.